- Americas

- Asia Pacific

- Europe

- Middle East and Africa

Metals ERP solution

Achieve sustainable growth with a tailored Microsoft™ technology solution

Metals systems shouldn’t be complex and inefficient

Are these problems slowing your metals company down?

Manual processes

Disparate systems

Infrequent demand forecasting

Poor visibility

Crowe Metals Accelerator, built on the Microsoft Dynamics 365™ platform, is designed to meet the unique needs of metals companies.

Prepare your metals business for future growth

Standardize more efficient business processes and increase productivity across multiple metal product types, metal manufacturing processes, and different end customer needs.

Make smarter decisions faster

Get accurate data and real-time analytics from your metals enterprise resource planning (ERP) solution. Use these analytics to maximize margins, minimize machine downtime, and increase customer satisfaction.

Enable faster innovation with continual updates

Gain access to the latest innovations from both Microsoft and Crowe rolled out in automatic updates.

Gain a competitive advantage

Take advantage of built-in Microsoft Azure™ artificial intelligence and machine learning to forecast customer demand and avoid costly machine downtime.

Crowe Metals Accelerator offers an ERP solution specifically designed for the metals industry.

Wire and cable

Manage your manufacturing processes for better cost tracking and product performance analysis.

Pipe and tube

Provide end-to-end visibility to inventory dimensions such as OD/ID, pipe schedule, tube gauge shape, and length to allow for faster order fulfillment.

Building products

From coil, sheet, plate, and long product processing to complex fabrication and assembly, easily manage the unique combination of process and discrete manufacturing in a single, end-to-end ERP solution.

Service centers

Get the tool set to help improve customer service, increase inventory visibility, and more effectively plan operations.

Wire and cable

Manage your manufacturing processes for better cost tracking and product performance analysis.

Pipe and tube

Provide end-to-end visibility to inventory dimensions such as OD/ID, pipe schedule, tube gauge shape, and length to allow for faster order fulfillment.

Building products

From coil, sheet, plate, and long product processing to complex fabrication and assembly, easily manage the unique combination of process and discrete manufacturing in a single, end-to-end ERP solution.

Service centers

Get the tool set to help improve customer service, increase inventory visibility, and more effectively plan operations.

Producers

Optimize material planning, integrate production control, and improve quality management.

Toll processors

Communicate in real time to manage inventory, production specifications, quality, shipping, and receiving.

Producers

Optimize material planning, integrate production control, and improve quality management.

Toll processors

Communicate in real time to manage inventory, production specifications, quality, shipping, and receiving.

An ERP solution built on the Microsoft platform and tailored by metals specialists

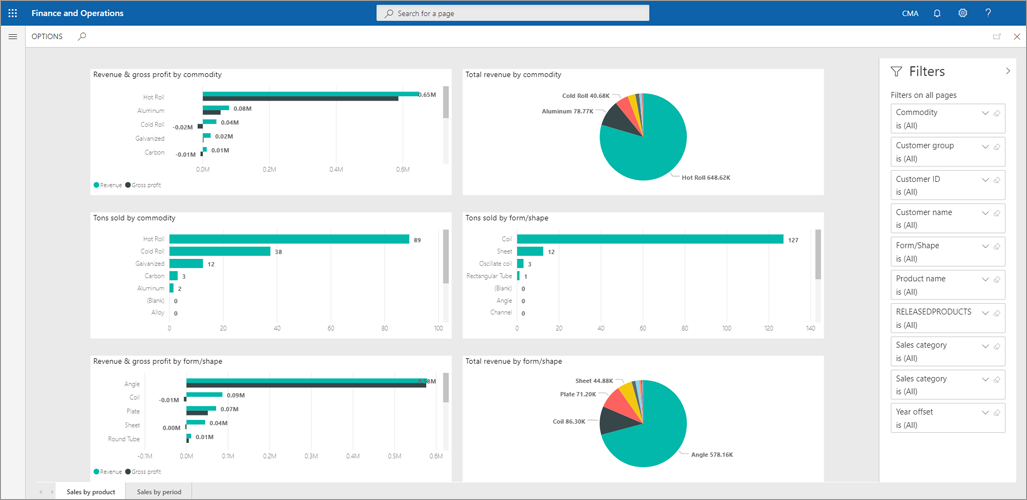

Metals sales analytics

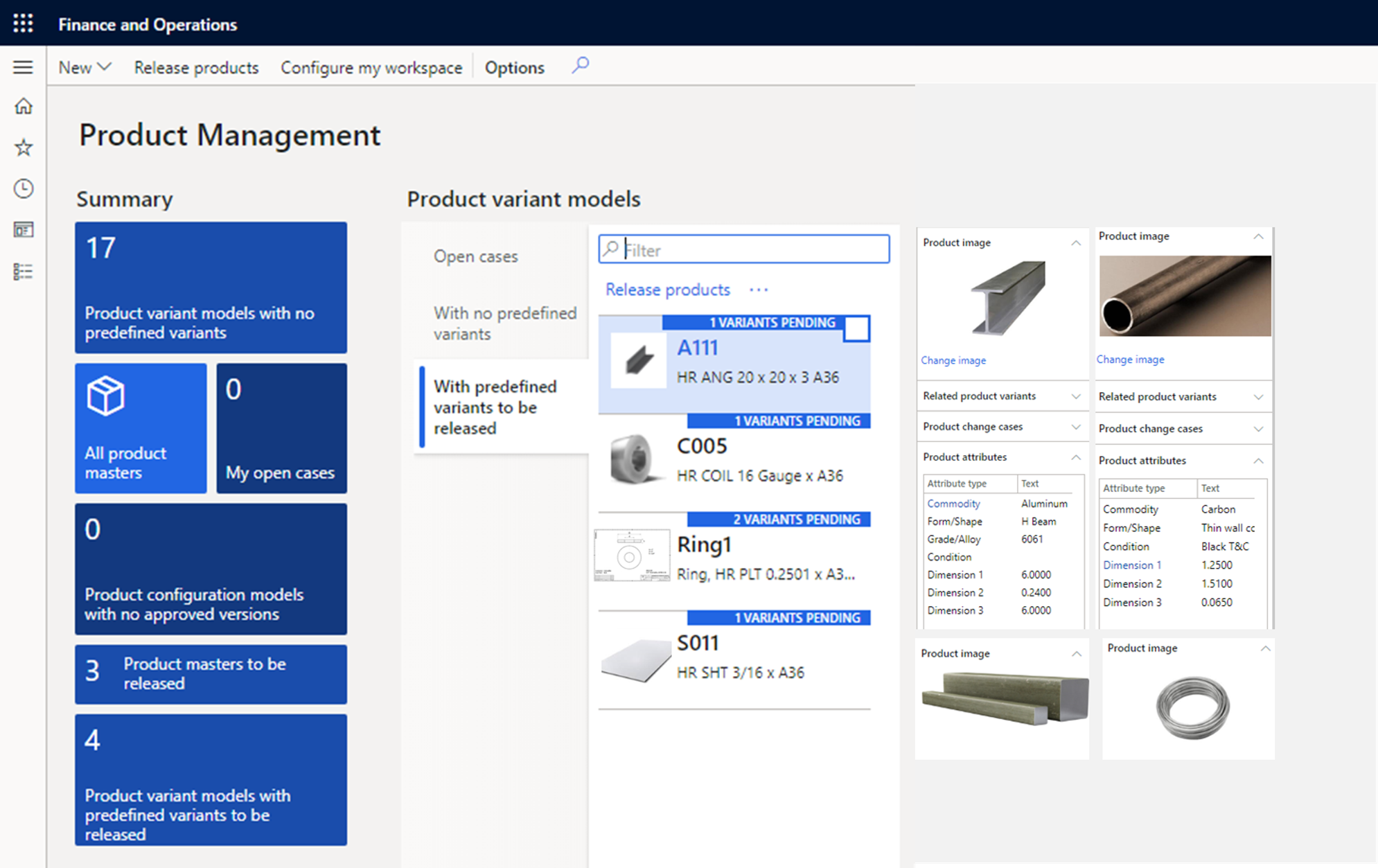

Inventory management

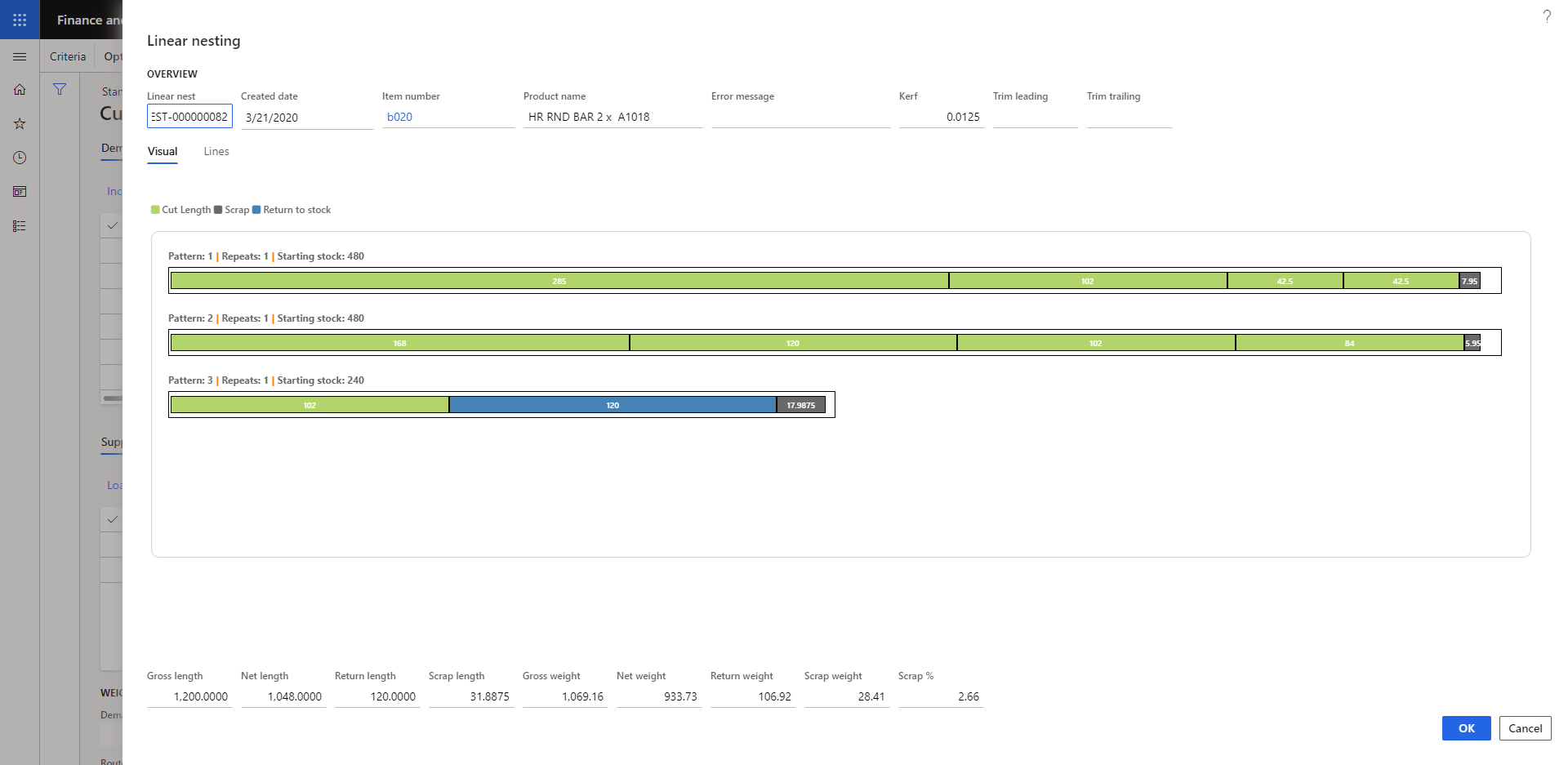

Nesting solution

Metals sales analytics

Metals sales analytics

Monitor manufacturing costs, inventory value, surcharges, and commodity markets.

Inventory management

Inventory management

Nesting solution

Nesting solution

Provide competitive quotes, deliver them quickly, and achieve potential savings on material costs with both linear and plate nesting integrated into quoting and planning.

Specification management

Inventory by dimension and attribute

Quality management

Flexible unit conversions

Specification management

Inventory by dimension and attribute

Quality management

Flexible unit conversions

Scrap and remnant material management

Parent-child material traceability

Actual and theoretical weight tracking

Optimized order entry

Scrap and remnant material management

Parent-child material traceability

Actual and theoretical weight tracking

Optimized order entry

Pricing built for metals

Mill test reports and product certifications

Pricing built for metals

Mill test reports and product certifications

Meet the Crowe team

See how our metals ERP works

Complete the form to let our team know you’re interested in a 30-minute demo. We’re ready to schedule a call, show you how it works, and answer any questions you might have.

Featured insights

<p>Changing technology priorities in the metals service center industry</p><p></p><p></p>

Microsoft, Dynamics 365, and Azure are trademarks of the Microsoft group of companies.